Mastering Route Optimization For Last-Mile Delivery

#route-optimization#last-mile-delivery#delivery-logistics#fleet-management#supply-chain-tech

November 8, 2025

Route optimization for last-mile delivery is all about figuring out the smartest possible paths to get packages from a distribution center to a customer's doorstep. This isn't just about using a standard GPS. It's a sophisticated process that juggles dozens of real-world variables to craft routes that save time, money, and headaches in the most challenging part of the supply chain.

Winning the Final Mile of Delivery

Think of the supply chain like a high-stakes relay race. The first few legs can be flawless, but if the final runner stumbles, the whole race is lost. That's a perfect analogy for last-mile delivery. It's the most critical - and by far the most difficult - part of getting a product to a customer. With e-commerce setting the bar incredibly high, a single late package can sour a customer's entire experience.

This final stretch is where carefully laid plans meet the real world. You're dealing with unpredictable traffic, narrow delivery windows, and sometimes tricky addresses. Trying to manage this chaos without a solid strategy is more than just inefficient; it's a direct path to losing money and customers.

The High Stakes of the Last Step

The numbers don't lie - the cost of a poorly managed last mile is massive. It's easily the most expensive part of the journey, eating up about 53% of total delivery costs. When deliveries fail because of a wrong address or a missed time slot, the cost skyrockets, averaging an extra $17.78 per failure.

The good news? Modern dynamic scheduling and route planning can slash these delivery costs by up to 25%. You can explore more last-mile delivery statistics to see the full picture.

This is exactly why route optimization for last-mile delivery has become an essential tool. It's the brain of your delivery operation, making sure every driver and vehicle is used as effectively as possible.

By intelligently sequencing stops and adapting to real-time conditions, route optimization turns a chaotic, costly process into a streamlined, predictable, and profitable operation. It's the key to winning that final, all-important leg of the race.

To put it in perspective, let's break down the common pain points and how optimization solves them.

Last-Mile Delivery At a Glance

| Challenge Area | Typical Problem | Impact of Optimization |

|---|---|---|

| Cost Control | High fuel consumption, driver overtime, and vehicle maintenance drain budgets. | Creates the shortest, most fuel-efficient routes, cutting operational expenses significantly. |

| Driver Efficiency | Drivers spend too much time on the road, completing fewer deliveries per shift. | Maximizes stops per route, allowing drivers to complete more deliveries without working longer hours. |

| Customer Satisfaction | Inaccurate ETAs, missed delivery windows, and failed attempts lead to frustrated customers. | Provides precise delivery windows and real-time tracking, building trust and loyalty. |

| Scalability | Manual planning breaks down as delivery volumes increase, leading to chaos and errors. | Automates complex planning, allowing businesses to scale their operations smoothly. |

This table highlights just how intertwined these challenges are. A single inefficient route doesn't just waste fuel; it delays deliveries, frustrates customers, and puts a strain on your entire operation.

Why Optimization Is No Longer Optional

Not too long ago, a dispatcher with a map and a spreadsheet might have been enough. For a small business with a handful of daily deliveries, that worked. Today, that manual approach simply can't keep up. The massive increase in delivery volume, combined with spiking fuel prices and customer demands for near-instant service, makes it obsolete.

A properly optimized system gives you a clear competitive edge:

- Reduced Operational Costs: You're not just finding shorter routes; you're cutting down on fuel, vehicle wear, and unnecessary overtime. Every mile saved goes straight to your bottom line.

- Increased Driver Productivity: When routes are logical and efficient, drivers can handle more deliveries in the same amount of time. This means you can grow your business without necessarily growing your fleet.

- Improved Customer Experience: Happy customers are repeat customers. Providing accurate ETAs, hitting specific delivery windows, and minimizing failed attempts are crucial for building that loyalty.

In the end, mastering route optimization for last-mile delivery isn't just a nice-to-have operational tweak. It's a core business strategy that's vital for staying competitive and profitable.

So, What Exactly Is Route Optimization?

At its heart, route optimization is the process of figuring out the absolute best path for a driver to take when they have multiple stops to make. This goes way beyond what your standard GPS app like Google Maps or Waze can do. Sure, they're great at getting you from Point A to Point B, but they just aren't built for the multi-stop chaos of last-mile delivery.

Imagine a single driver has 100 different packages for 100 unique addresses. The number of possible routes is staggering - literally more than there are atoms in the known universe. Trying to eyeball the "best" route on a map is a fool's errand. This is where route optimization for last-mile delivery comes in, acting as a grandmaster chess player for your entire fleet.

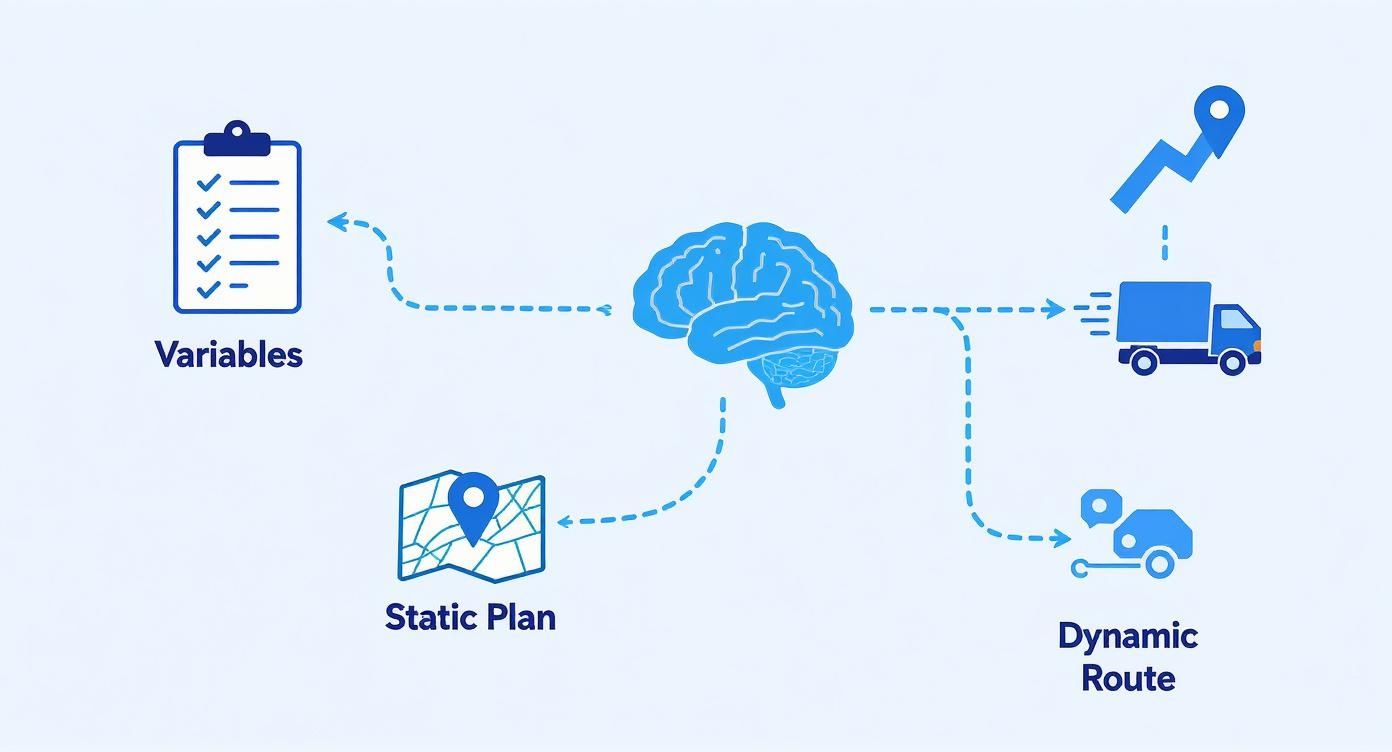

It's a digital problem-solver that juggles dozens of real-world variables all at once to spit out a plan that's not just about the shortest distance, but about the smartest sequence that saves the most time and money.

The Brains Behind the Operation

Route optimization software does a lot more than just look at a map. Think of it as the central nervous system for your delivery operations, constantly taking in new information and making adjustments.

It's constantly crunching data on a huge number of factors, including:

- Traffic Patterns: Using both live and historical data to steer drivers clear of gridlock.

- Delivery Windows: Making sure packages show up within the specific timeframes customers were promised.

- Vehicle Capacity: Not trying to stuff 150 boxes into a van that can only hold 100.

- Driver Schedules: Factoring in lunch breaks, shift end times, and which drivers are even available.

- Service Time: How long does it actually take to park, grab the right package, and walk it to the door? It all adds up.

By weighing all these elements together, the software generates routes that are not just fast, but also realistic, efficient, and cost-effective.

Static Planning vs. Dynamic Optimization

It's really important to understand the massive difference between old-school route planning and modern, dynamic optimization. They might sound like the same thing, but they're from different planets.

Static route planning is like printing out MapQuest directions before a road trip. The route is set in stone at the beginning of the day, and that's that. If a surprise accident shuts down the highway, the driver is on their own, often leading to huge delays and frustrated customers.

Dynamic route optimization, on the other hand, is like having a live co-pilot who is constantly checking for a better way to get there. It adapts to new information as it happens.

For example, if a nasty traffic jam suddenly pops up, a dynamic system can instantly reroute a driver around it. If a customer calls with a last-minute pickup request, the system can find the closest driver and slot that stop into their route without throwing their whole day into chaos.

This ability to pivot on a dime is what makes dynamic route optimization for last-mile delivery so incredibly powerful. It turns a rigid, easily broken plan into a flexible and intelligent operation. If you want to dive deeper into the core concepts, these Demystifying Delivery Route Planning Basics Ai Sustainability Significance resources offer a great overview. This proactive approach means efficiency isn't just a plan - it's a constant, ongoing reality.

How Routing Algorithms Actually Work

At the heart of any route optimization software, you'll find a set of powerful algorithms. You can think of them as the engine that transforms a chaotic list of addresses into a clear, efficient game plan for your drivers. These aren't just simple map directions; they are sophisticated problem-solving models built to navigate a labyrinth of real-world delivery constraints.

To really get a feel for what these algorithms do, it helps to understand the classic logistical puzzles they were designed to solve. These foundational problems show why simple pen-and-paper planning just doesn't cut it in today's demanding delivery world.

The Original Routing Puzzle: The Traveling Salesperson

The simplest version of this puzzle is called the Traveling Salesperson Problem (TSP). Picture a tourist in a new city who wants to see every landmark. Their goal is to figure out the single most efficient path that hits every spot without backtracking, covering the shortest distance possible.

Sounds easy enough for a handful of stops, right? But the complexity blows up exponentially with each new destination. For a route with just 10 locations, there are over 360,000 possible paths. Add five more stops to make it 15, and that number skyrockets to a staggering 1.3 trillion. This is the core challenge: sifting through a mind-boggling number of options to find that one perfect route.

Adding Real-World Complexity: The Vehicle Routing Problem

The TSP is a great starting point, but last-mile delivery is way messier than a tourist's sightseeing trip. That's where the Vehicle Routing Problem (VRP) comes into play. The VRP builds on the TSP's foundation but layers in all the messy, unpredictable variables that delivery businesses deal with every single day.

Now, instead of one salesperson, you're managing an entire fleet. This forces the algorithm to juggle a whole new set of crucial questions at the same time:

- Vehicle Capacity: Which packages should be loaded onto which truck to make sure no vehicle is over its weight or space limit?

- Time Windows: How do you sequence the stops so you arrive at a customer's location within their requested 9 AM to 11 AM window?

- Driver Schedules: How do you map out a day that respects mandatory driver breaks and gets them back to the depot on time?

- Service Times: How long should a driver realistically spend at each stop to park, find the right package, and make the handoff?

This is where route optimization software truly shines, processing all these moving parts to build plans that work in the real world.

As the infographic shows, it's about balancing all these competing factors to create either a fixed daily plan or one that can adapt on the fly - a task that's simply impossible to do well manually.

Finding The "Best Fit," Not Just The Fastest

Modern routing algorithms rarely try to find the absolute single perfect route by checking trillions of options. That would take forever. Instead, they use smart shortcuts known as heuristics and metaheuristics to find an exceptionally good, near-perfect solution in a matter of seconds.

Think of it like this: instead of trying every single key on a massive keyring, a heuristic algorithm uses clues - like the shape of the lock or the brand name - to intelligently narrow down the possibilities and find the right key almost instantly.

These algorithms are also flexible. They can be tuned to weigh different goals based on what your business cares about most. One company might want to prioritize minimizing fuel costs above all else. Another might be focused on hitting every single time window to keep their customers happy.

Good software lets you define those priorities, ensuring the routes it generates aren't just efficient, but are actually aligned with your specific business objectives. This is the real magic behind route optimization for last-mile delivery - it takes an impossibly complex puzzle and turns it into a daily competitive advantage.

Building Your Modern Delivery Tech Stack

A top-tier delivery operation isn't built on a single piece of software. It's a complete tech stack - a set of tools that talk to each other to run the whole show. Think of it less like a single app and more like a smart home system where your thermostat, security cameras, and lights all work together seamlessly. Your delivery tech needs to function the same way.

This integration is what separates a static, pre-planned route from a living, breathing operation that can adapt on the fly. When every part of your system shares data in real-time, dispatchers can make brilliant decisions, drivers get where they're going faster, and your customers actually know what's happening. This is the real secret behind effective route optimization for last-mile delivery.

The Core Software Components

Software is the command center, the brain that crunches all the numbers and spits out a smart delivery plan. A modern platform isn't just one program; it's a collection of specialized tools that cover every single step of the delivery journey. This approach keeps information flowing and prevents the kind of data black holes that plague old-school, manual operations.

Here's what every solid delivery tech stack needs:

- Route Optimization Engine: This is the core of it all. It's a powerful algorithm that figures out the absolute best multi-stop routes, juggling all your unique constraints like vehicle space, driver hours, and those tricky customer time windows.

- Real-Time GPS Tracking: You need a live map showing where every truck is, right now. This isn't just for watching dots on a screen; it's about seeing how the plan is unfolding and being able to react instantly when something goes wrong.

- Proof of Delivery (POD) App: Your drivers need a mobile app. Period. It lets them grab signatures, snap photos of delivered packages, and jot down notes. This digital trail is your best friend for settling disputes and keeping everyone accountable.

- Customer Communication Platform: This is the tool that stops the "Where is my order?" calls before they even start. It automatically sends customers tracking links, accurate ETAs, and status updates, keeping them happy and informed.

These are the must-haves. But the real magic happens when they're all connected, feeding data into one central hub. For a deeper dive, our guide to essential fleet management system features covers these tools in more detail.

The Role of AI and Machine Learning

These days, the best route optimization platforms are getting a serious boost from Artificial Intelligence (AI) and machine learning. These aren't just buzzwords; they take your tech stack from a simple planning tool to a predictive system that learns and adapts. AI isn't just looking at what's happening now - it's figuring out what will happen next.

By chewing on historical data - everything from traffic patterns to how long a driver actually spends at each stop - machine learning can predict route times with uncanny accuracy. AI-powered systems can even re-route drivers in the middle of their day based on live traffic, helping you dodge delays and save fuel. We're seeing companies using this tech to hit on-time delivery rates of over 95% while slashing costs by up to 30%. You can discover more insights about these optimization strategies on WorkWave.com to learn more.

This predictive capability is a total game-changer. Instead of just solving today's routing puzzle, the system learns from every single delivery. It gets smarter over time, making tomorrow's routes even more efficient than today's.

Essential Hardware for Your Fleet

If software is the brain, then hardware provides the eyes, ears, and legs of your delivery operation. These physical devices are out in the field, collecting the raw data that makes the entire system work. Without good data coming in, the software is just guessing.

The key hardware pieces include:

- Driver Smartphones or Ruggedized Devices: This is the driver's connection to the mothership. It's where they run the POD app, get their route updates, and send back GPS information.

- Vehicle Telematics and GPS Units: These are more than just trackers. They're hardwired into the vehicle to report on engine health, fuel usage, and even driver behaviors like hard braking or speeding. This gives you a much deeper understanding of your fleet's performance and safety.

When you pair intelligent software with reliable hardware, you create a powerful, closed-loop system. You gain complete visibility and control over every part of your last-mile operation, which is exactly what you need to cut costs and keep your customers smiling.

Putting Your Route Optimization Strategy into Action

Alright, you understand the "what" and "why" of route optimization. Now, let's get into the "how." Moving from theory to practice isn't about just flipping a switch on new software. It's about laying a solid groundwork of clean data, setting clear goals, and - most importantly - getting your team excited about the change.

A smart rollout is what separates a frustrating tech headache from a game-changing efficiency boost. It all starts with the lifeblood of any logistics operation: your data. Your shiny new routing software is a powerful engine, but it runs on data. Feed it garbage, and you'll get garbage routes.

Start with a Data Health Check

Before you even think about optimizing a single route, you have to get your data in order. Think of it like a chef prepping ingredients before service - if your produce is rotten, the final dish is doomed. The same goes for your addresses, service times, and vehicle information.

Start by auditing what you have. Look for the little things that cause big problems: typos in street names, wrong zip codes, missing apartment numbers. A single bad address can send a driver on a wild goose chase, throwing their entire day off schedule. This initial cleanup isn't just a chore; it's the most critical first step.

If you're juggling thousands of addresses and complex data streams, it might be worth exploring professional data modernization services to ensure your foundation is rock-solid from day one.

The success of your route optimization strategy hinges on data quality. A small investment in cleansing and validating your address book and operational parameters upfront will pay massive dividends in efficiency and accuracy down the road.

Define Your Real-World Rules

With clean data in hand, it's time to teach the software how your business actually works. This is where you translate your operational playbook into rules and constraints the algorithm can understand. It's how you make the software think like your best dispatcher.

Some of the key parameters you'll need to set include:

- Vehicle Capacities: How much can each truck really hold? Define the maximum weight and volume.

- Driver Schedules: Set start and end times, mandatory breaks, and depot locations.

- Service Times: Be realistic about how long a stop takes, from parking the truck to getting a signature.

- Delivery Windows: Lock in any hard time commitments you've made to customers.

Don't forget about regulations. You need to account for things like the FMCSA's short-haul exemption, which can directly impact driver hours and planning. Getting these rules right ensures the software generates routes that are not only fast but also feasible and compliant.

Choosing the Right Approach for Your Business

Not every business needs a fully autonomous, AI-driven routing system from the get-go. The best approach depends entirely on your scale, complexity, and resources. Choosing the right level of automation is key to a successful implementation.

Here's a quick breakdown to help you find the right fit:

Comparing Route Optimization Approaches

| Approach | Best For | Key Benefits | Limitations |

|---|---|---|---|

| Manual | Small fleets (under 5 vehicles) with simple, local routes. | Low cost, high flexibility for on-the-fly changes. | Extremely time-consuming, prone to human error, not scalable. |

| Semi-Automated | Growing businesses (5-20 vehicles) with recurring routes. | Balances cost and efficiency, introduces basic optimization. | Relies on dispatcher expertise, can't handle real-time changes well. |

| Fully Dynamic | Medium to large fleets (20+ vehicles) with complex daily needs. | Maximizes efficiency, adapts to traffic and new orders in real-time. | Higher initial investment, requires clean data and team training. |

Ultimately, the goal is to pick a system that solves today's problems without boxing you in tomorrow. You can always start with a semi-automated solution and graduate to a fully dynamic one as your business grows.

Get Your Team Trained and Onboard

You can have the best technology in the world, but it's useless if your people don't use it. Your drivers and dispatchers are the heart of the operation, and a smooth rollout hinges on their buy-in.

Start by explaining the "why." Show them how this new tool makes their lives easier - less time in traffic, more predictable finish times, and fewer headaches.

Provide hands-on training that focuses on what they'll actually use every day: the driver's mobile app and the dispatcher's dashboard. A great way to start is by running a small pilot program with a few of your most tech-savvy drivers. This lets you iron out the kinks and gather feedback before going live with the whole fleet. Empowering your team with great training turns them into enthusiastic partners, ensuring you get every bit of value from your investment.

The Future of Last-Mile Logistics

The world of last-mile delivery is on the verge of a serious shake-up, powered by tech that promises a faster, greener, and far more efficient future. The familiar sight of a delivery van pulling up to the curb might soon share the road with a whole fleet of autonomous helpers. This isn't science fiction; it's the next wave of logistics, and it's already starting to change how packages get to our front doors.

A huge part of this shift is the push toward sustainable logistics. With environmental rules getting stricter and customers demanding eco-friendly options, companies are swapping out their gas-guzzlers for electric vehicle (EV) fleets. This throws a whole new set of variables into route optimization for last-mile delivery. Software now has to think about battery range, charging times, and where to find charging stations. The best route for an EV isn't just about the shortest distance - it's about making sure the vehicle can finish its rounds without running out of juice.

The Rise of Autonomous Fleets

Beyond just going electric, the most exciting change will be the arrival of autonomous technology. This isn't a one-size-fits-all solution, but a mix of different automated systems designed for specific delivery jobs.

We're already seeing the first generation of these tools pop up:

- Autonomous Ground Vehicles: Think small, self-driving robots zipping along sidewalks. They're perfect for handling short-distance drop-offs in crowded city centers or across sprawling corporate campuses.

- Delivery Drones: For getting a small, urgent package to a rural home, drones are a game-changer. They can fly right over traffic, cutting delivery times from hours to minutes.

As companies adopt EVs, robots, and drones to meet green targets, they're also finding ways to get around old problems like city traffic. Businesses that get on board with these innovations are expected to see labor productivity jump by as much as 40% in the next decade.

The future of last-mile logistics isn't about getting rid of human drivers. It's about building a hybrid ecosystem where people handle the tricky, complex deliveries, and autonomous systems take care of the routine, predictable ones with incredible efficiency.

Orchestrating a Hybrid Delivery Network

The real magic - and the biggest challenge - will be managing this mixed fleet of vehicles. The route optimization software of tomorrow will need to be like an orchestra conductor, deciding which delivery goes to a van, a sidewalk bot, or a drone. It will have to coordinate all their movements perfectly to create a seamless handoff from the warehouse to the customer's doorstep.

This evolution calls for a smart combination of artificial intelligence and automation. To see how these technologies are already being used in other areas of business, you can check out our guide on AI automation for business. This level of coordination is the key to unlocking a truly optimized last mile - one that's not just faster and cheaper, but a whole lot more sustainable, too.

Frequently Asked Questions

If you're digging into route optimization, you've probably got questions. It's a big topic. Let's tackle some of the most common ones I hear from business owners trying to get a handle on their delivery operations.

How Is This Different from Google Maps?

This is the classic question, and it's a great one. Think of it this way: Google Maps is fantastic for getting one person from Point A to Point B. It's a consumer tool.

Route optimization software, on the other hand, is a professional logistics tool built to solve a much bigger puzzle. It's designed for a fleet of vehicles that have to visit dozens or even hundreds of stops. It doesn't just find a path; it builds an entire operational plan, factoring in real-world business rules like vehicle capacities, specific delivery time windows, and driver work hours.

How Long Does It Take to See a Return on Investment?

You'll see the impact faster than you might think. While every business is different, most companies start noticing significant savings within the first few months. The ROI comes from very tangible places: less fuel burned, fewer hours of driver overtime, and a dramatic cut in the time your team spends manually planning routes.

A solid route optimization platform can slash fuel and labor costs by 15-30% right out of the gate. The efficiency gains don't stop there - you're also empowering each driver to complete more deliveries, which directly boosts revenue and profitability.

What Kind of Business Is a Good Fit for This Technology?

Honestly, any business running a fleet of vehicles with multiple daily stops will see a benefit. It's not limited to one or two industries. We see it used everywhere:

- E-commerce and Retail: Managing the final, crucial step of getting packages to customers' doorsteps.

- Food and Beverage Distribution: Getting time-sensitive products to restaurants and grocery stores on schedule.

- Field Services: Coordinating technicians for HVAC, plumbing, or electrical appointments.

- Third-Party Logistics (3PL): Juggling the complex delivery demands of multiple clients at once.

If your daily reality involves figuring out who goes where and when, route optimization is built for you.

Is It Difficult for Drivers to Learn a New System?

Not anymore. The old-school systems could be a nightmare, but modern platforms are designed for the person behind the wheel. Most come with a simple mobile app that feels just like using Waze or Google Maps for navigation.

The best ones give drivers everything they need in one place: a clear stop list, turn-by-turn directions, and easy ways to capture proof of delivery. A little bit of training is all it takes, and most drivers quickly come to love having a smart, predictable plan for their day.

Ready to build a delivery operation that's tough, scalable, and powered by smart technology? Pratt Solutions specializes in creating custom cloud-based solutions and automation to solve exactly these kinds of logistical puzzles. We bring the deep technical expertise needed to get your fleet management dialed in and drive real business results.

Learn more about our custom software engineering and IT consulting services at john-pratt.com